REAR AXLE

REAR AXLE

Construction:

- It is mostly live axle in commercial vehicles and dead axle in cars.

- Two half-shafts are used to transmit the power from differential.

FORCES ON REAR AXLE

1. Shear stress due to weight of the body

2. Driving Thrust

During torque transmission the thrust has to be transmitted to body through frame by radius rod.

3. Torque reaction

Torque reaction will be there during torque transmission and braking. This will oppose the propeller shaft rotation causing torsional and bending stress.

4. Side Thrust

Side thrust or pull due to side load on the wheel and due to cross winds during cornering.

Types of Rear axles

Depending upon the method of supporting the rear axles and mounting the rear wheels

1.Semi or non-floating axle

2.Full-floating axle

3.3/4 Floating axle

1.Semi floating axle

- Half-shaft inner end is splined into the differential and other end is supported by bearing inside casing.

- The axle shaft both carries the weight and transmits torque.

- The bending load causes shear stress at point A.

- So axle takes weight, driving torque and side thrust.

- It is simple, cheap, using in a cars, light duty trucks and half road vehicles.

Dis-advantage:

- The diameter of the axle shaft should be larger for the same torque transmission.

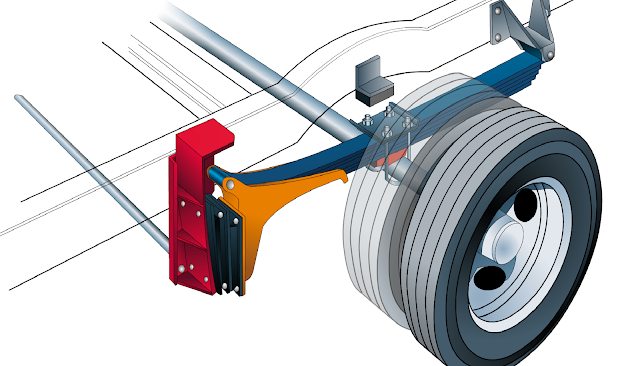

2.Full-floating axle

- A bearing spindle is attached to the axle housing, and a set of bearings in a separate wheel hub.

- Tapper Roller bearing takes any side thrust, as it placed outside of the axle casing.

- Axle shaft is used only for transmitting the driving torque and the weight of the vehicle is carried by the axle casing and tyre.

- Full-floaters are considerably heavier and stronger.

- It is used in heavy vehicles.

- It is costlier.

3. 3/4 Floating axle

- This type of axle is a combination of full and semi floating type.

- In this, bearing is located between the axle casing and wheel hub axle shaft. The wheel hub runs on the axle housing. So axle do not have to withstand any shearing or bending action due to the weight of the vehicle, which are taken up by the axle casing through hub and bearing.

- It was once used in cars and light duty vehicles.

types of rear axle

Rear axle casing:

- It is used as a cover for rear axle.

Based on the dismantling of differential, it is classified as,

- Split type

- Banjo type (or) separate carrier type

- Salisbury (or) Integral carrier type

1. Split type

- Axle casing is made of 2 halves and bolted together in assembly.

- The main dis-advantage is in case of repair, whole of the rear axle has to be removed as a unit then disassembled.

- This type is obsolete now.

2. Banjo type (or) separate carrier type

- The tubular axle casing section is of one piece type, made of pressed steel& welded together to resist bending load.

- The final drive assembly is carried in a separate carrier and bolted to the axle casing.

- In case of repair, the half-shafts can be removed and inserted back into the casing from the sides and differential assembly can be removed by opening the bolts.

- It is used in commercial vehicles.

3. Salisbury (or) Integral carrier type

- This is similar to the banjo type construction except the differential housing tubes are pressed and welded on its sides. It is called as Unitized carrier housing.

- It is used in rear wheel drive cars.

Its really informative post and i found some very helpful points in it. Thanks for sharing. best tyres in UAE

ReplyDelete

ReplyDeleteRenault duster shock absorbers

Renault Kwid shock absorbers

Hyundai Greta dicky shocker

Nissan Micra dicky shocker

Renault kwid dicky shocker

Renault duster dicky shocker

For anyone dealing with a car issue, knowing how to maintain your rear axle is important. If your car won’t start due to a dead battery, services like flat battery jump start service can save you a lot of hassle.

ReplyDelete